realization of customer wishes

Pioneering manufacturing technology

The core competence of cms electronics is the realization of customer requirements in the area of manufacturing electronic assemblies, systems and devices.

The spirit of innovation, the constant development of know-how by our employees and the growth strategy of management make our success story possible.

Increasing production capacities and the rapid development of our manufacturing technologies at our locations in Austria, Hungary and Germany are setting the course for future projects.

The strengths of our locations, e.g. the favorable cost structure of the plant in Hungary, the specialization in medical technology and for small series in Germany or the high degree of automation of Austrian production, are used specifically in the interests of our customers.

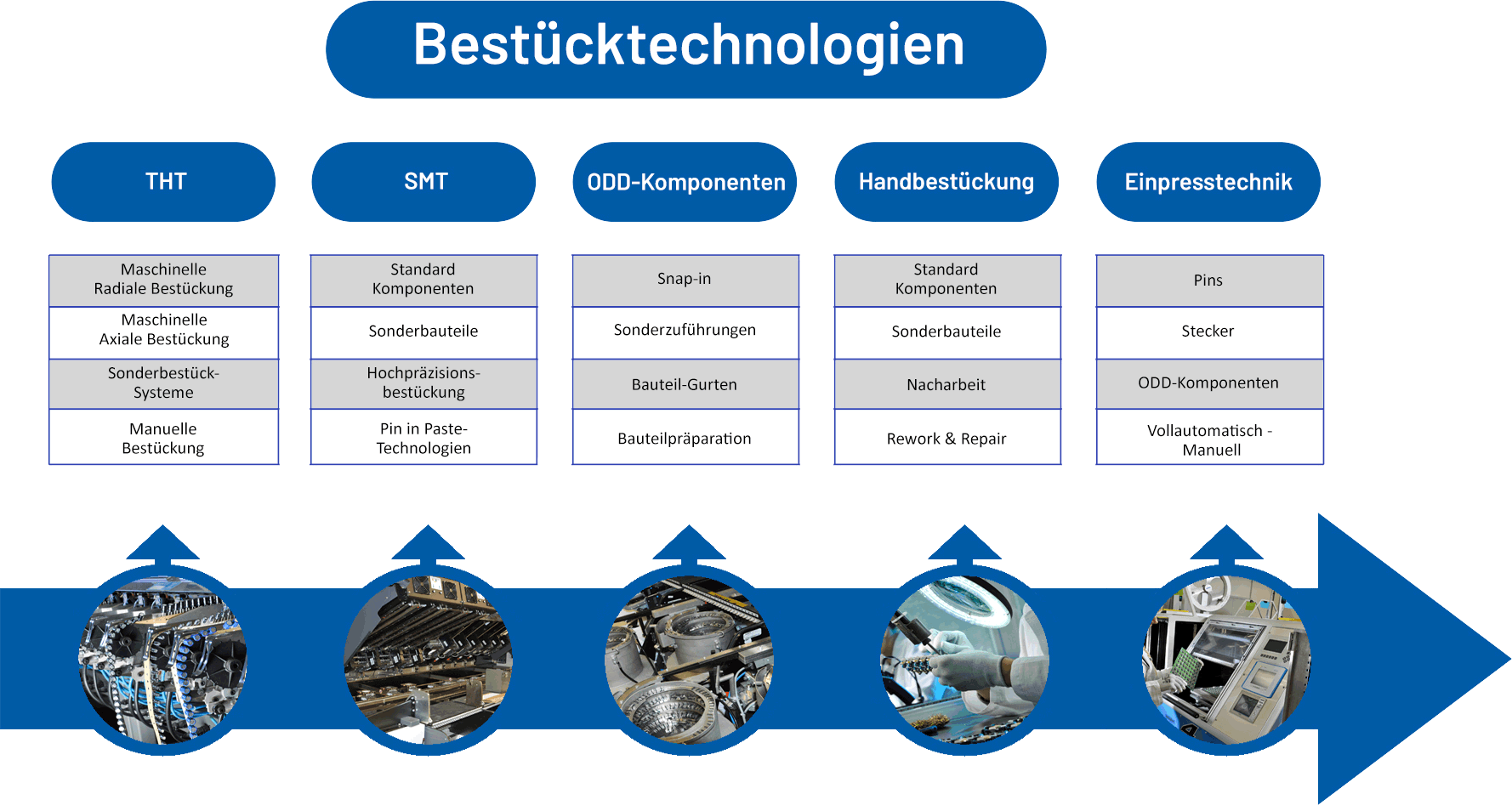

Our technology portfolio

ECOFLEX – An all-rounder for testing

cms electronics specializes, among other things, in the development of automated test systems.

It all started with a combination of a rotary indexing table and a 6-axis robot. We have now reached our current high point with the realization of our fully automated test system, the ECOFLEX.

Optical drilling of printed circuit boards

Cms electronics plays a pioneering role in precision electronics.

A specially designed and developed drilling machine is used for optical drilling of PCB mounting systems. The system, which is set up in its own fully air-conditioned room, is designed for 6σ process capability at 50µm.

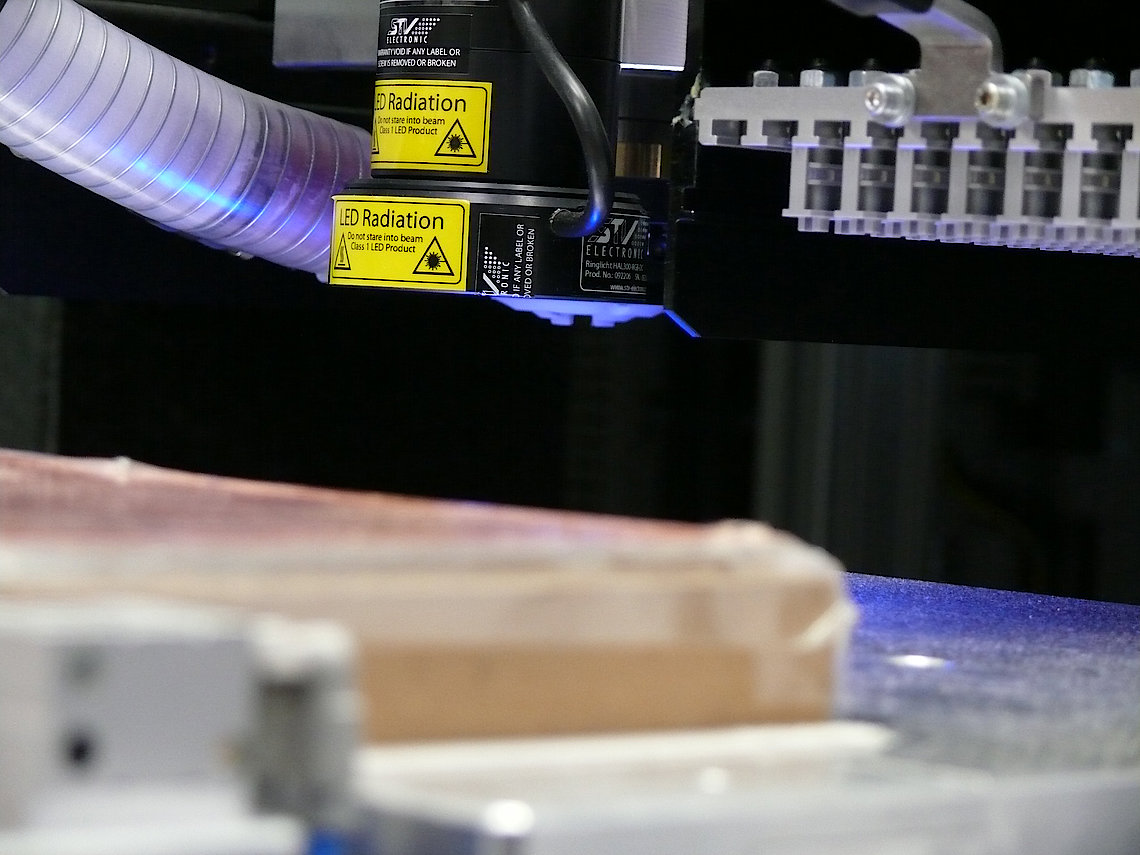

Laser optical high-precision assembly

The ongoing development and miniaturization require the setting of ever smaller components with ever smaller tolerances at high speed and process reliability.

In the past, the shape and size of housings and circuit boards were crucial and enabled process reliability in the range of 3σ.